Application

This mushroom packing machine is designed to efficiently pack various types of fungi, including flammulina velutipes, hypsizygus marmoreus, shiitake, and agaricus bisporus. It accommodates both fresh and dried products, making it a versatile choice for any operation.

The structure of this product

Control system with four axletrees for precise maneuvering.

Human-computer interface, PLC control, and multiple safety measures.

Prevents cutting mushrooms with accurate feeding and precise product positioning; exhaust device included.

Photoelectric detection, automatic tracking, feeding, and positioning functions.

Hermetical head sealing air-tight bag device.

Hermetical head sealing air-tight cutting prevention device.

Head press-button sponge exhaust devices on both sides.

Reciprocal head seal with packing height adjustable up to 150mm.

Transverse seal width of 10mm and longitudinal seal with 6 teeth.

Standard supply conveyor belt length of 2m (customizable).

Packing material: OPP, blank film membrane surface with no holes.

Three-side exhaust function and leakage detector for vacuum levels of -40KPA or more.

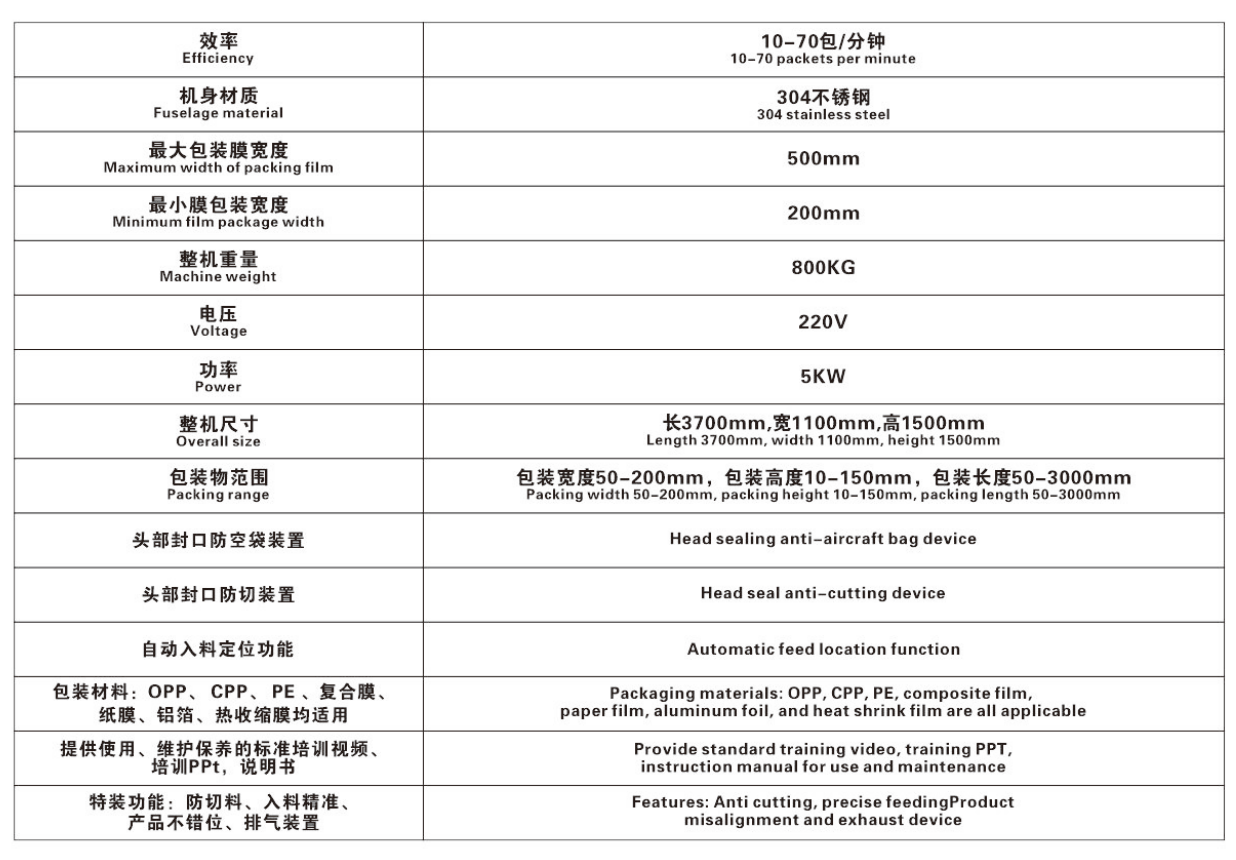

Technical Parameter

Remarks: :

Sandard training videos, training PPT and instruction for use and maintenance are provided.

The technical parameters are the debugging range of the machine, and the actual parameters are subject to the customer's product size.

Mushroom tray packing machines expertly handle the careful packaging of delicate fungi. High speed packaging machines like these are essential for quick, efficient processing in the mushroom industry. The mushroom bagging machine automates the bagging process, boosting productivity. Flow packing machines provide the flexibility needed for various mushroom types, ensuring each is packaged to perfection.