Application Cases

High-speed packaging machines are the pulse of modern production, swiftly wrapping products with precision. Vacuum packaging machines remove air to prolong shelf life, while plastic wrap packaging machines offer a tight seal, ensuring freshness and protection. These machines are the guardians of product integrity in the packaging world.

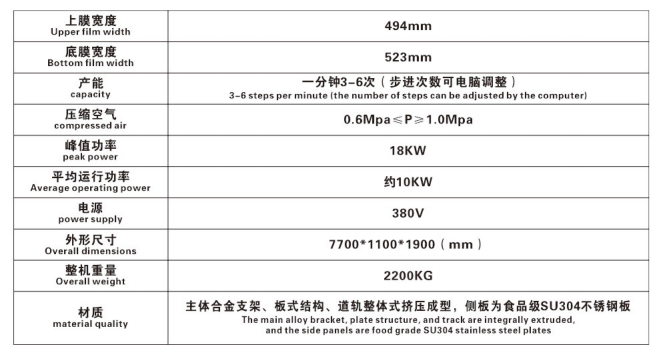

Technical Parameters

The Advantages of this Product

1. Adopting the German original imported vacuum pump, pumping 200 cubic meters per hour, the limit vacuum degree can reach 0.1mbar, 5.5kw strong power

2. The photoelectric tracking system adopts the original imported color code sensor, which can sense all colors and output strong signals to ensure the use of color film, and make the color film can be aligned with the bottom film forming area.

3. Servo system control, high speed and high precision stepper speed, and the adoption of medium inertia servo motor drive system, using CNC machining center arc interpolation technology, the selection of motion control module, can arbitrarily adjust the speed of the servo motor, and ensure that the running progress in plus or minus 2 mm, to ensure high speed and high precision operation. The upper and lower membranes have adjustable pneumatic devices, which will not cause the problem of film deviation.

4. The upper and lower membranes are equipped with pneumatic tightening system, making the film stable and reliable. The top and bottom film adopt advanced air swelling roller fixation and positioning technology, easy to operate, low failure rate

5. Equipped with powerful waste recovery system, to ensure that the waste on both sides of the bottom film is timely and effective recovery

6. Equipped with separate transverse and longitudinal cutting tools according to customers' products. The crosscutting tool works independently with a single tool and is centrally controlled by computer. Each mold is equipped with a set of upper and lower longitudinal cutting tools to ensure timely and rapid adjustment and replacement.